CONTACT

CONTACT US NOW

BABY

TEETHING

BABY

TOYS

BABY

FEEDING

PET

PRODUCTS

Year Experience

Custom Projects Annually

Brands Cooperation

Step1

Step1

We begin with understanding your product idea, target market, and required compliance standards. Whether it’s a silicone teether, feeding item, or a custom toy, our team helps refine your concept and provide professional feasibility guidance.

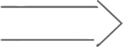

Step2

Step2

Our design team creates 2D sketches and 3D models based on your approved concept. We help optimize structure, softness, thickness, and safety features to ensure your silicone product meets both aesthetic and functional standards

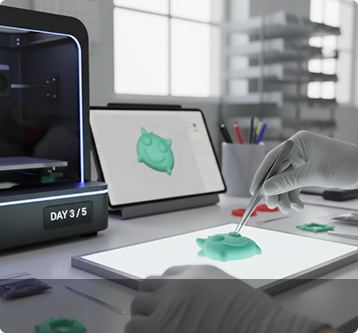

Step3

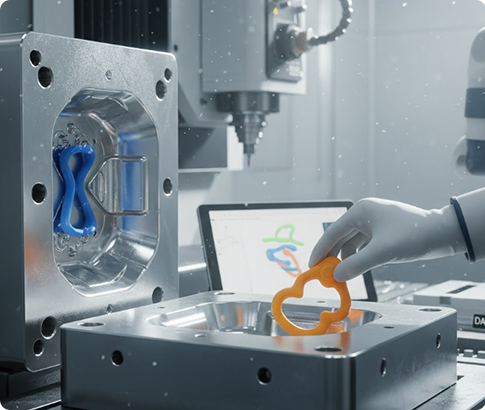

Step3

We quickly turn the approved design into real prototypes using silicone material or CNC molds. Customers can evaluate size, hardness, texture, and safety details before moving to mold development.

Step4

Step4

With over 100+ skilled workers and a stable production system, Melikey ensures efficient and consistent manufacturing. All silicone materials are food-grade, BPA-free, and fully compliant with global baby product standards

Step5

Step5

Every batch goes through strict QC, covering raw material safety, hardness test, pulling test, color inspection, and final packaging review. We follow standards required for global baby product export such as EN71, CPSIA, LFGB, FDA, REACH.

Step6

Step6

We provide customized packaging options including color boxes, blister cards, reusable bags, and private-label packaging for branding enhancement. All goods are checked before shipping to guarantee consistency.

Reply within

Quotation within

Prototyping

Mass production